Differential pressure transmitter is one of the widely used instruments in industrial production, through which many physical parameters can be measured, such as pressure, liquid level and flow rate, which is of great significance in industrial production.

Differential pressure transmitter is widely used in industrial production, and the effect of measuring industrial flow is very remarkable.

It is usually used with orifice Flowmeter, V-cone Flowmeter, elbow Flowmeter, Weiba Flowmeter, Aniuba Flowmeter and so on.

As the detection and transformation part of the process control system, the differential pressure transmitter converts the process parameters such as differential pressure (pressure), flow rate and liquid level of liquid, gas or steam into a unified standard signal (such as DC 4mA~20mA current), which is used as the input signal of the display instrument, operator and regulator, so as to realize the continuous detection and automatic control of the production process.

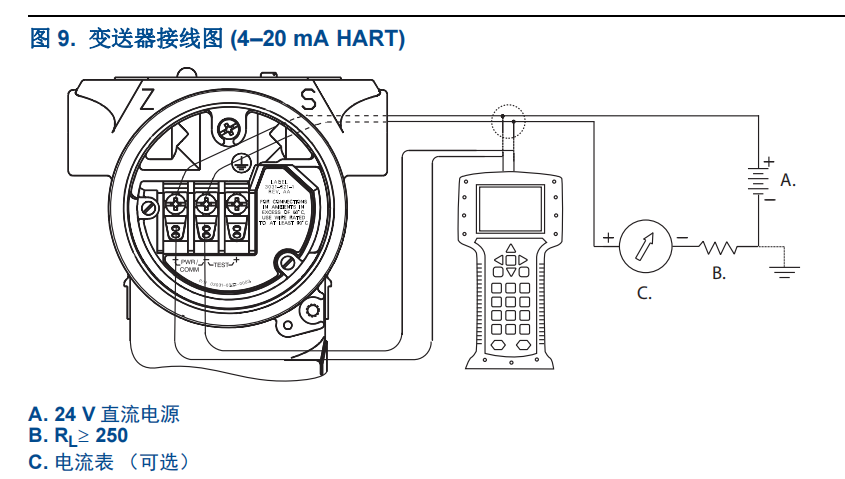

Wiring steps of differential pressure transmitter:

1.

Remove the housing cover on one side of the field terminal (FIELD TERMINALS).

two。.

Connect the positive lead to the "+" terminal (PWR/COMM) and the negative lead to the "-" terminal.

3.

Ground the housing to comply with local grounding regulations.

4.

Make sure the ground is properly grounded.

The instrument cable shielding layer must:

a.

Trim the shell of an electronic device that is flat and does not touch the transmitter.

b.

If the cable is wired through the junction box, it should be connected to the next shield.

c.

Properly grounded at the power supply end.

5.

If transient protection is needed, it should be carried out with reference to the grounding instructions in the section "grounding of transient protection terminals".

6.

Unused conduit connections should be plugged and sealed.

7.

Re-cover the shell cover.

Note:

Shielded twisted pair should be used for best results.

24 AWG or thicker wiring with a length not exceeding 1500 meters (5000 feet) should be used.

According to the actual situation, a dripping ring can be made when installing the wiring.

The arrangement of the drip ring shall be such that its bottom is lower than the wire pipe joint and the transmitter housing.

* the installation of transient protection terminals does not provide transient protection unless the 3051 housing is properly grounded.

* when running, do not arrange the signal cable and the power cord in the conduit or on the open cable tray, or near the large electrical equipment.

* do not connect live signal lines to test terminals.

The energy in the signal line may damage the test diode in the terminal.

瞬变保护接线端子的接地在电子装置外壳的外面和端子仓中提供有接地端接装置。在安装瞬变保护接线端子时,使用这些接地点。建议使用 18 AWG 或更大规格的接线把外壳接地点与大地 (内部或外部)连接。The grounding of the transient protection terminal is provided with a grounding termination device on the outside of the electronic device housing and in the terminal compartment.

Use these locations when installing transient protection terminals.

It is recommended that 18 AWG or larger wiring be used to connect the shell grounding to the earth (internal or external).

Installation requirements of differential pressure transmitter.

Liquid applications:

Install the shunt connector on the side of the pipe.

Install the transmitter on the side or bottom of the shunt connector.

The discharge / exhaust valve should be made upward when installing the transmitter.

Gas applications:

1.

Install the shunt connector on the top or side of the pipe.

two。.

Install the transmitter on the side or top of the shunt connector.

The installation position of the differential pressure transmitter on the process pipeline is related to the tested medium. in order to obtain a better installation effect, attention should be paid to the following conditions:

* prevent the transmitter from coming into direct contact with corrosive or overheated tested media.

* prevent dregs from depositing and blocking in the suction pipe.

* the length of the positive and negative pressure tubes on both sides should be the same as possible.

* the liquid column head in the positive and negative pressure tube should be kept flat.

* 正负压两侧引压管内的液柱压头应保持平